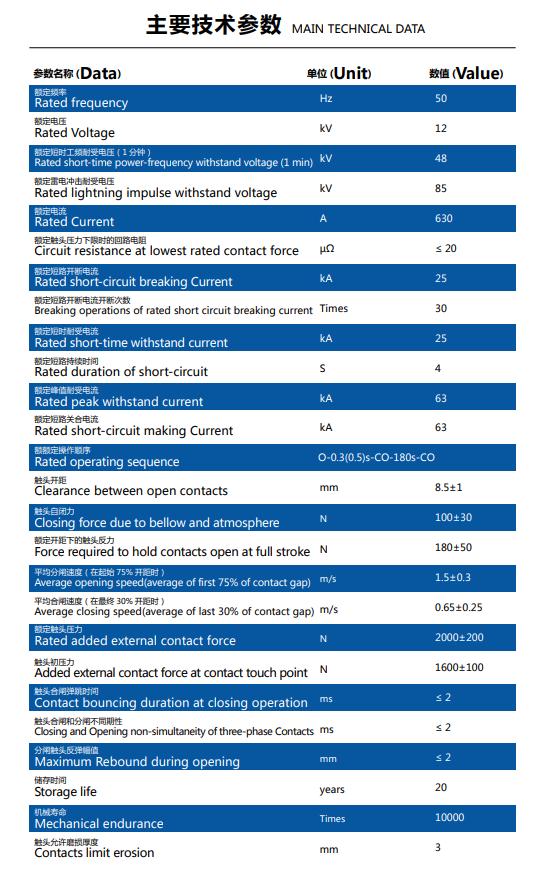

Vacuum Interrupter For Inflatable Cabinet(133)

Brief description of the product:

Vacuum arc extinguishing chamber, also known as vacuum switch tube, is the core component of power switch. Its main function is to make the circuit quickly extinguish the arc and suppress the current after cutting off the power supply through the excellent vacuum insulation in the tube, so as to avoid accidents and accidents. It is mainly used in power transmission and distribution control systems, as well as distribution systems such as metallurgy, mining, petroleum, chemical industry, railway, broadcasting, communication, industrial high-frequency heating, etc. It has the characteristics of energy saving, material saving, fire prevention, explosion prevention, small volume, long service life, low maintenance cost, reliable operation and no pollution. Vacuum arc extinguishing chamber is divided into arc extinguishing chamber for circuit breaker, load switch and vacuum contactor. The arc extinguishing chamber for circuit breaker is mainly used for substations and power grid facilities in the power sector, and the arc extinguishing chamber for load switch and vacuum contactor is mainly used for end users of power grid.

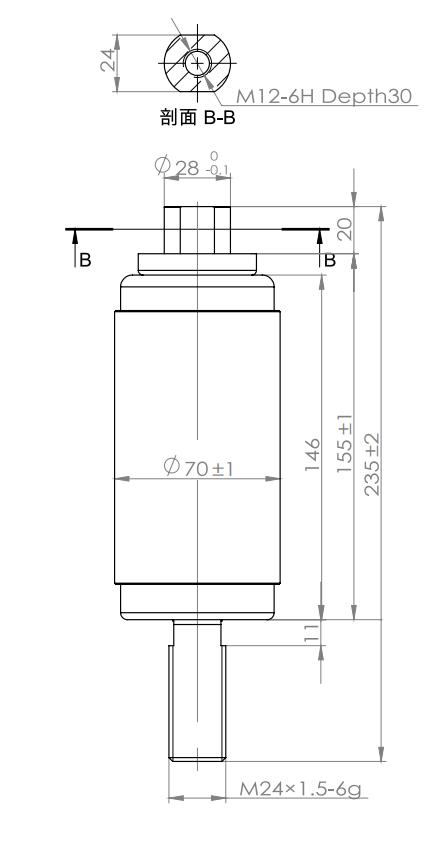

The vacuum interrupter includes a guide sleeve to control the moving contact and protect the sealing bellows from twisting, which would drastically shorten its life.

Although some vacuum-interrupter designs have simple butt contacts, contacts are generally shaped with slots, ridges, or grooves to improve their ability to break high currents. Arc current flowing through the shaped contacts generate magnetic forces on the arc column, which cause the arc contact spot to move rapidly over the surface of the contact. This reduces contact wear due to erosion by an arc, which melts the contact metal at the point of contact.

Only few manufacturer of vacuum interrupters worldwide produce the contact material itself. The basic raw materials, copper and chrome, are combined to a powerful contact material by means of the arc-melting procedure. The resulting raw parts are processed to RMF or AMF contact discs, with the slotted AMF discs deburred at the end.